Bessel Motorsports, Inc. the home of the exceptional Bessel splayed caps have captured the racing industry once again with its patent – pending Bessel Block Supports. Which provide significantly improved block support by adding a .003″ pre-load in the engine block.

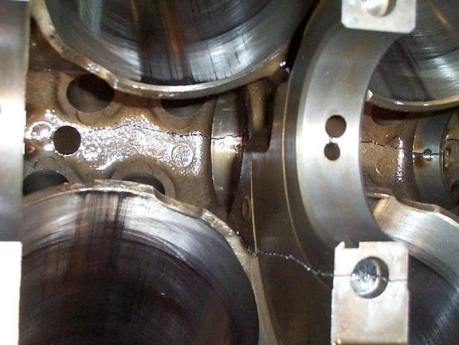

Many diehard Ford enthusiasts knows, the 302 Ford factory blocks are notorious for splitting at 500 – 550 hp and so is the new 360 Chrysler Magnum blocks. These blocks cannot withstand the increased levels of horsepower of today’s power additives such as stroker kits, large amounts of compression, NOS, turbos, and superchargers. The consequence is always the same the block will split down the lifter valley area, which quickly destroys everything.

The solution is easy the new Bessel Block Support, but lets look at why these blocks split in the first place. The answer has always been right on top of your motor. The intake manifold is the reason for this weak design and destruction, when you bolt up a 302 Ford, or a 360 Chrysler Magnum manifolds your Intake bolts will go straight down into the block, and this puts a wedge into your blocks. As your horsepower number go up you are causing a great amount of stress and flexing on the block. With the wedge in the block it simply cannot withstand the levels of high loads, and is unable, to live up to advances in engine power.

Now, lets look at the 350 Chevy manifold how many of those blocks have you seen split down the middle? Almost none…….. the reason being the Intake manifold does not put a wedge in the block. Your small block Chevy manifold bolts go in at angle putting a pre-load into your block.

The Bessel Block design puts a .003″ pre-load in your block (the block will pull itself together like the small block Chevy manifold does) and is held in position with six dowel pins and cap screws.

The Bessel Block support system overwhelmingly increases the blocks stability. These are precision block supports, which are designed from the centerline of the camshaft. The Bessel Block Supports must be installed with a bridge-port or CNC machine.

Another Example / Explanation

The 302 Ford blocks are notorious for splitting at 500 – 550 hp and so is the new 360 Chrysler Magnum blocks.

Do you know why?

The answer is simple it is your intake manifold causing all of your problems along with cap walk. What happens is when you bolt up a 302 Ford and 360 Chrysler Magnum manifold your bolts will go straight down and what this does is puts a wedge into your blocks. When you start creating decent horsepower and your caps start moving inward they will egg-shape and cause the cap to lose its register. When this goes unattended for a period of time it will put stress on the hardware holding your cap in place. This will push the stud or main bolt over enough to crack the stud housing.

Once this occurs the wedge in your block that was put there by the intake manifold will automatically split the block in half because of the weak design. If you look at a small block Chevy the intake design is totally different. When they install the manifold the bolts go in at an angle putting a pre load into the block and pulling it together.